A processing plant is similar to the human body; each system within needs to function properly both together and independently from other systems to be healthy.

About RTI’s Analytical Lab Capabilities

Large process plants depend on water that is often purified through ion exchange resins. The resins are critical for removing hardness and organics from clarified water before it goes to high pressure boilers. A critical question for water plant managers is this: Are the resins in my system doing their job, and how long will they be able to sustain their current performance for my system?

Ion exchange resin performance can be affected by both the health of the resin and its fouling level, both of which can affect the ability of the resin to process an adequate amount of water. Unhealthy resin and/or fouled resin will result in lower throughput. It is critically important to measure the health and fouling levels of resins on a regular basis to proactively avoid prolonged periods of poor water system performance.

There are few high quality resin labs in the US that are set up to answer those questions quickly and effectively. RTI’s resin lab is particularly effective on three critical dimensions of resin analysis:

- Industry leading turnaround time for typical resin analyses, averaging less than 5 business days.

- Not only measuring the current health and fouling levels of resins as received, but also measuring those same items in the after cleaning form of the resin, providing critical new information that will aid the water plant in performance decision making.

- Providing recommendations for action based on both the results from the analyses and over 20 years of resin testing experience.

The RTI Resin Lab is your most effective tool for analyzing resin condition and improving resin performance.

RTI Lab Capabilities

The RTI Lab has the equipment and experience to provide water plants with the most effective resin analyses in the industry today:

- GE Sievers 900 TOC Analyzer

Panalytical X-ray spectrometer to measure metals in resins and particulates - ASTM procedures for salt split, total capacity and moisture content

- Additional analytical capabilities

- Lab personnel with over 45 years of resin analytical experience

Lab Capabilities Overview

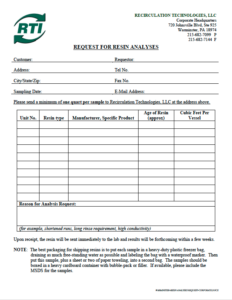

Request for Resin Analyses

Our Services

Your Full Service Resource For Water System Improvement!